Penetrant Electrostatic Spray System

Electrostatic Spray Gun For Applying Liquid Penetrant

Wet Application System

Electrostatic guns are highly economical penetrant application systems, offering unique advantages in NDT.

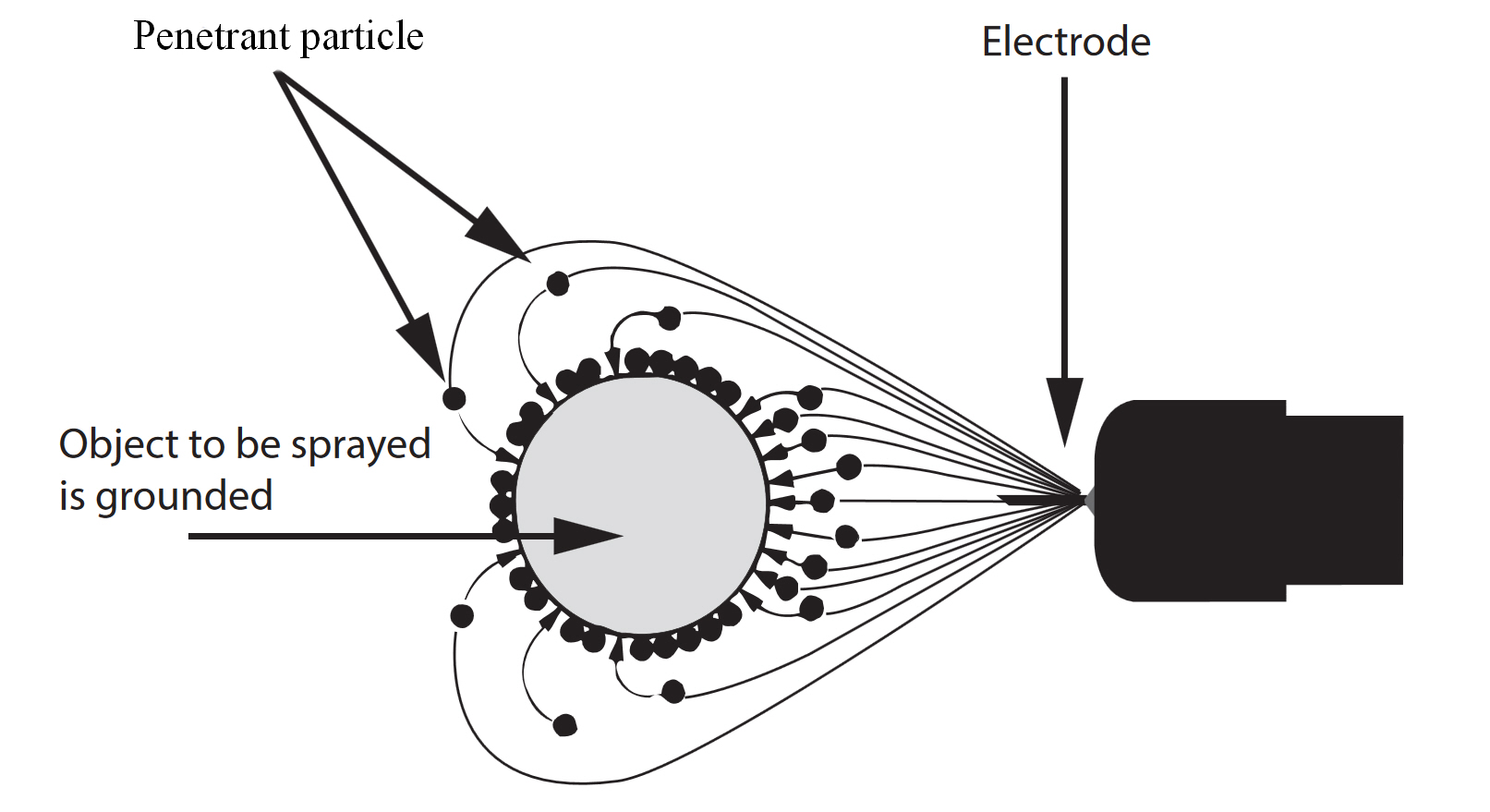

Due to the homogeneous alignment of the electrostatic field lines and the penetrant particles being charged with the same polarity, the atomization of the liquid penetrant is ideal for achieving extremely thin and uniform penetrant coverage, even on complex geometry.

This system is for liquid penetrant (wet application) only. For powder developer (dry application) then please click here to view the product page for the Developer Electrostatic Spray System.

Save time and reduce waste

The penetant, which is electrostatically charged by the spray gun, is attracted to all sides of the grounded object. This ‘wrap-around effect’ saves time, and depending on the component geometry, it may only need to be coated from one side. This effect can also reduce waste penetrant significantly compared to non-electrostatic penetrant application systems.

Which Electrostatic Spray System do I choose?

Electrostatics are used in a wide range of industries so it can be hard to know what you need for NDT if you are not familiar with Electrostatic Spray Systems or Electrostatic Spray Guns.

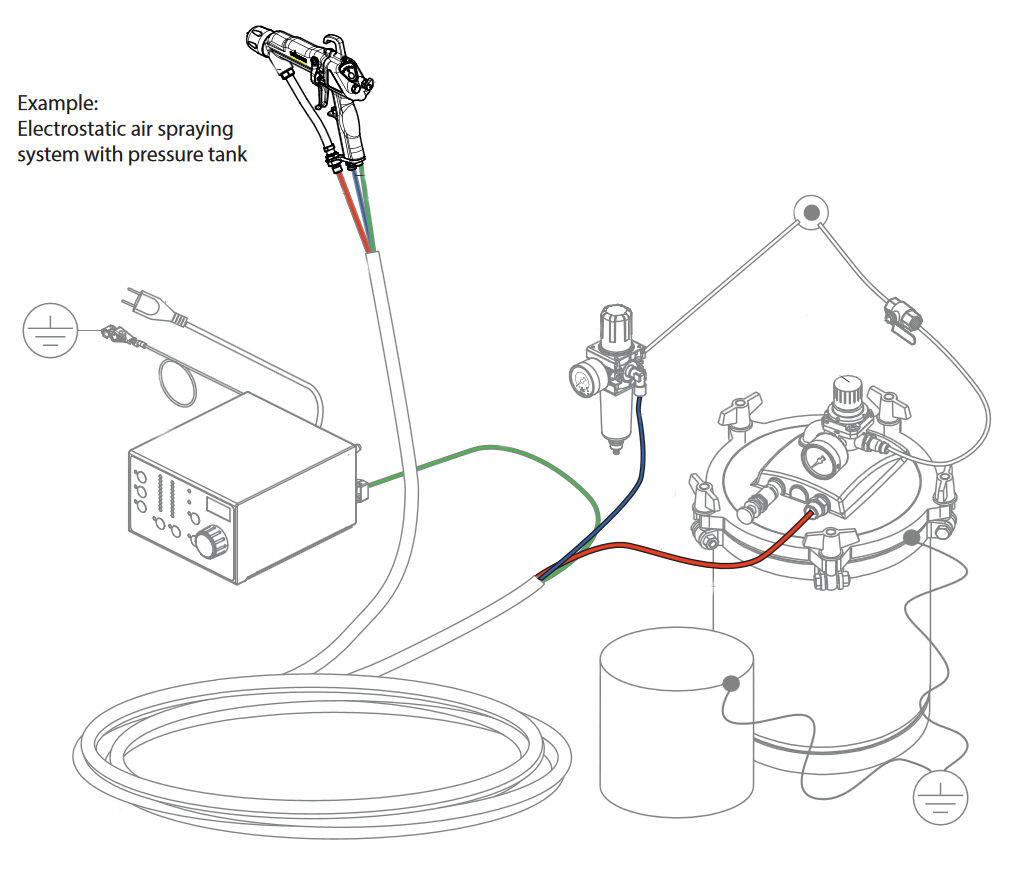

The 3 key parts of an Electrostatic Spray System are the electrostatic spray gun, the controller (power pack) and the pale (pressure tank). The gun is activated using a trigger for application, the controller is used to generate the electrostatic fields to charge the penetrant and the pale which holds bulk liquid penetrant.

Our standard Penetrant Electrostatic Spray System for Wet Application includes the following:

- Wagner GM5000EA Spray System.

- 20 Litre pressure vessel.

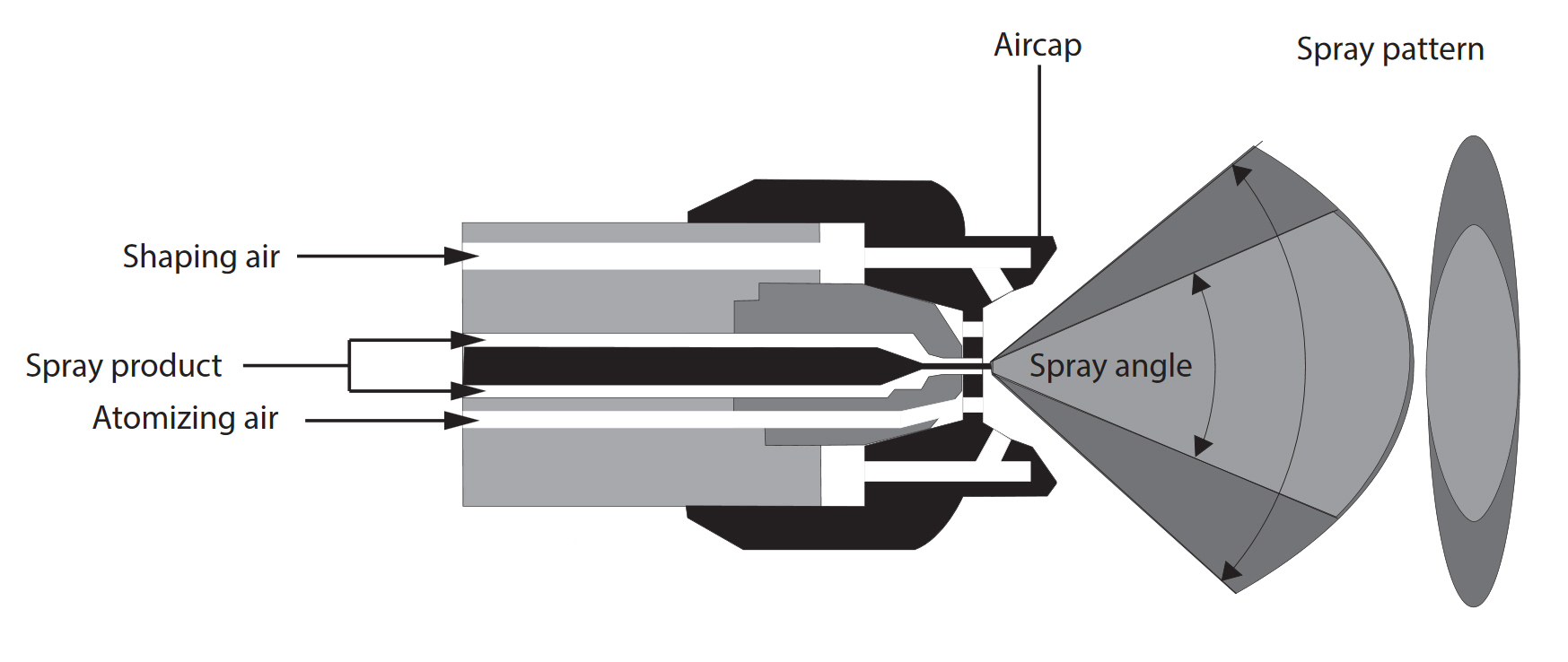

- Aircap AF 5000 1.0 - 1.4mm

- Nozzle AF 5000 - 1.0mm

- Wagner GM5000EA Gun

- Twin 7.5m hose set.

- VM500 Controller- Can be wall mounted.

Stainless steel construction - All wetted parts to be stainless (or plated brass where necessary) with stainless steel liner/pale.

While there will be some specialist applications that require different configurations and accessories, the above will cater for the vast majority of requirements in NDT. However Johnson & Allen can supply different types of aircaps and nozzles if a different spray pattern is sought to the default.

Johnson & Allen can also supply critical spares packages for customers requiring these.

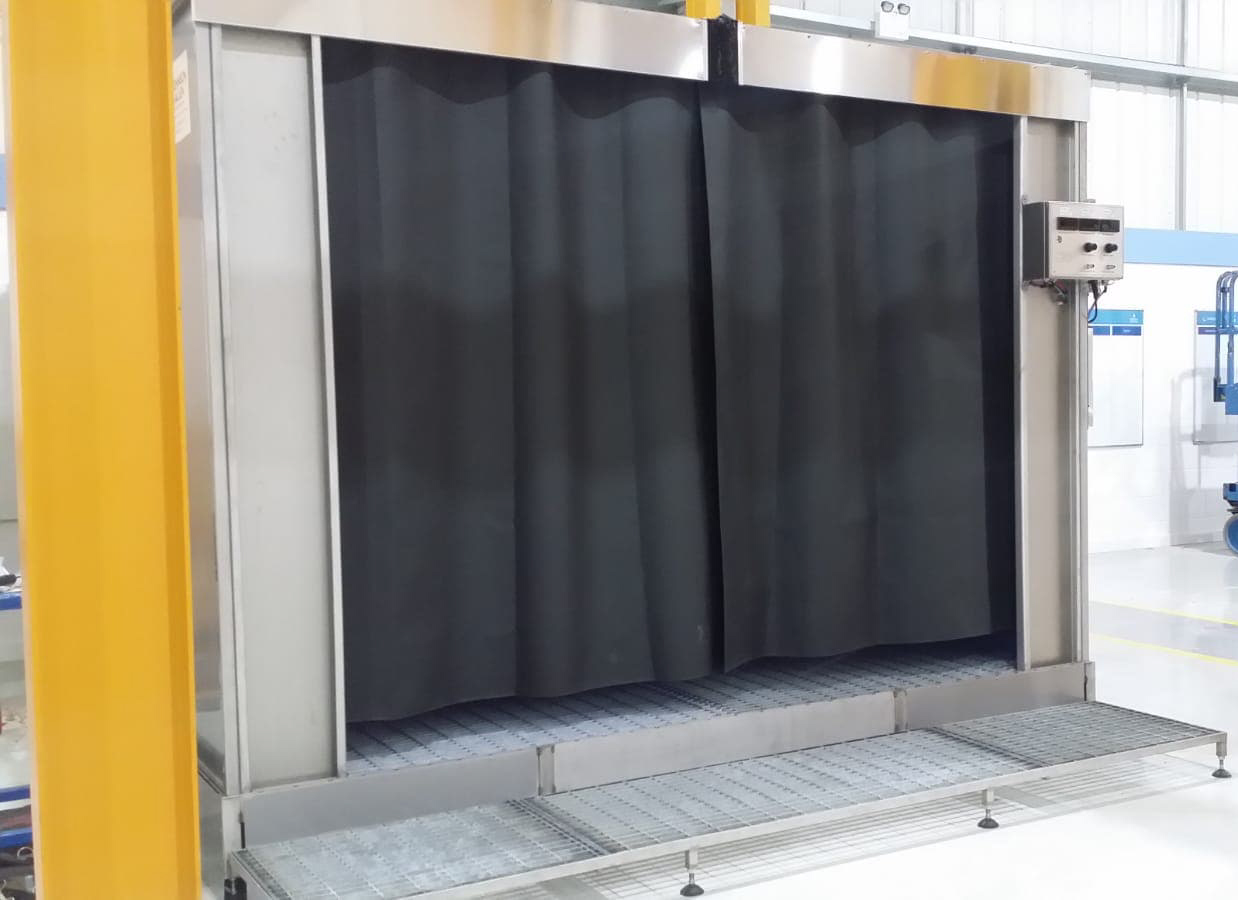

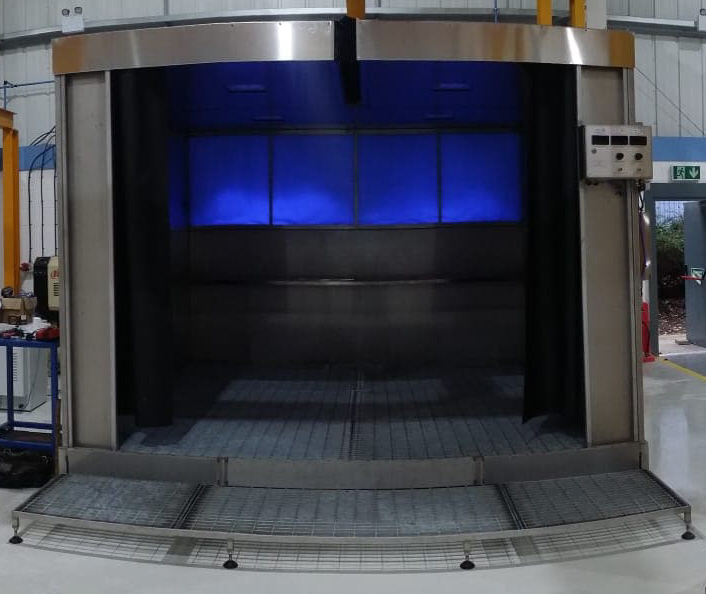

Air Extraction Booths

The electrostatic spraying equipment may only be operated in defined spraying areas and in accordance with the EN 12215 standard or under comparable ventilation conditions. Suitable extraction is necessitated for airborne droplets, over-spray and vapours.

Johnson & Allen can consult, manufacture and install NDT spray booths if required for customers without those capabilities.

What else do I need?

Along with suitable extraction and a mains supply, the Electrostatic Spray System will require a compressed dry air supply of at least 100 PSI pressure. If a supply of this pressure is not available then please consult Johnson & Allen as lower pressures can sometimes be used if close to 100 PSI.

If the air supply is not dry/clean then it is recommend an Eliminizer (or similar) be used to filter moisture and dirt from the air supply before connecting to the Electrostatic Spray System.

Installation and training

Johnson & Allen can undertake the installation of any Electrostatic System we supply and training is available for customers not familiar with their basic operation as part of any proposal - Johnson & Allen is here to make NDT easy.